Emission Report

PRESENTS

Air Pollution Control Basics

Building Emissions

Buildings and enclosed structures are among the most common sources of air

contaminant emissions. Construction and demolition transfer stations, recycling centers, and manufacturing plants, for example, can emit dust. Compost buildings, wastewater buildings, and MSW transfer stations can emit malodors. Chemical plants, sewage treatment plants, and industrial wastewater plants can emit hazardous air pollutants.

The Environmental Record’s Emission Report presents this chapter in Air Pollution

Control Basics as an introduction to building emissions and typical treatment methods.

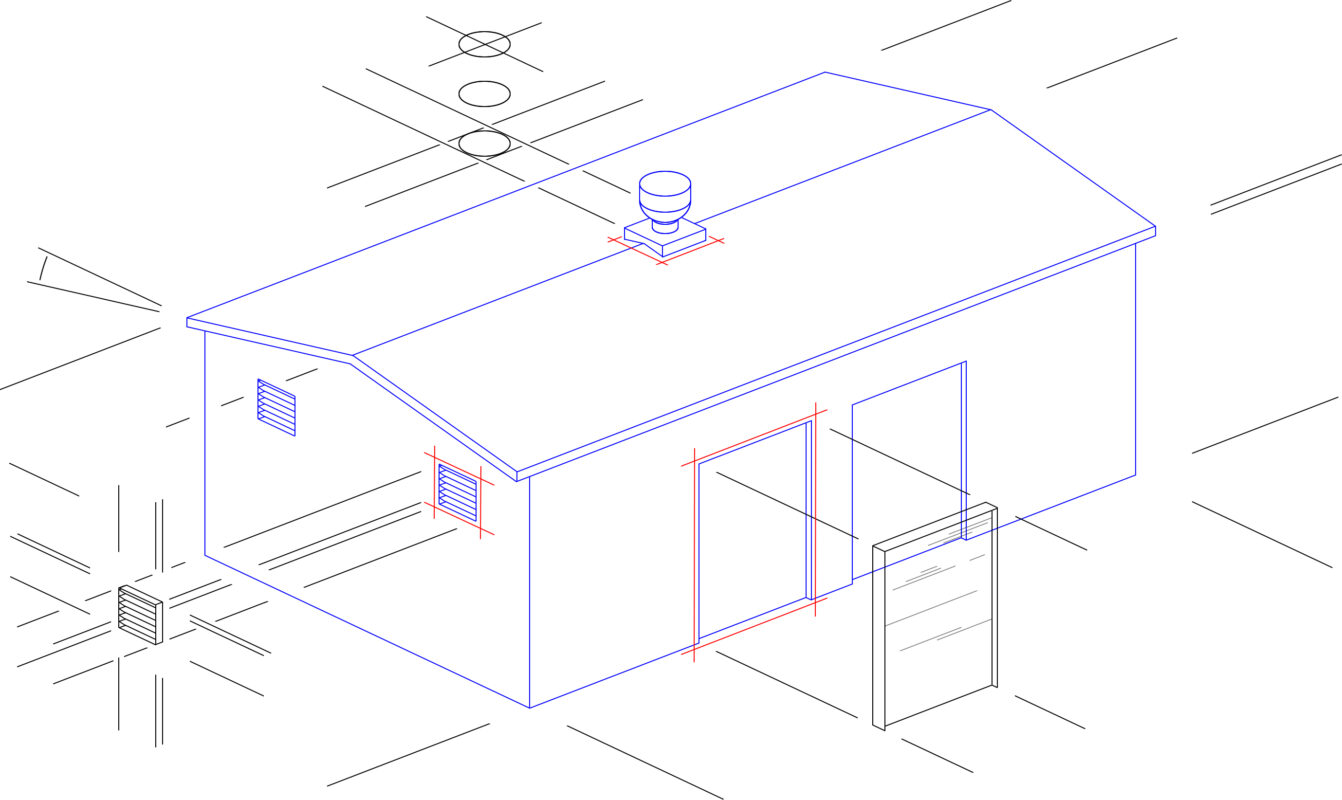

Emission Points

Air contaminants will escape buildings and enclosed structures through any available opening. Common emission points include exhaust fans, louvres, vents, and doors.

Any crack or crevice can allow contaminants to escape, so it is important to completely seal buildings and enclosures. High-speed truck doors can reduce crosswind and drag-out emissions by limiting the amount of time doors are open.

Negative pressure can be created inside a building by the use of a ventilation system that draws in more air than it releases back. Applying negative pressure to interior airspace can be extremely helpful in limiting emissions, yet open doors, exhaust fans, and vents will still allow contaminants through. Other emission points to be aware of are broken windows, conveyor holes, electrical chases, hatches, man doors, and perforated siding and soffit.

Categories of Emissions

There are three types of air contaminants that are primarily emitted from buildings and enclosed structures: dust, odor, and hazardous air pollution. Likewise, there are coinciding air pollution control technologies: dust control, odor control, and hazardous air pollution control.

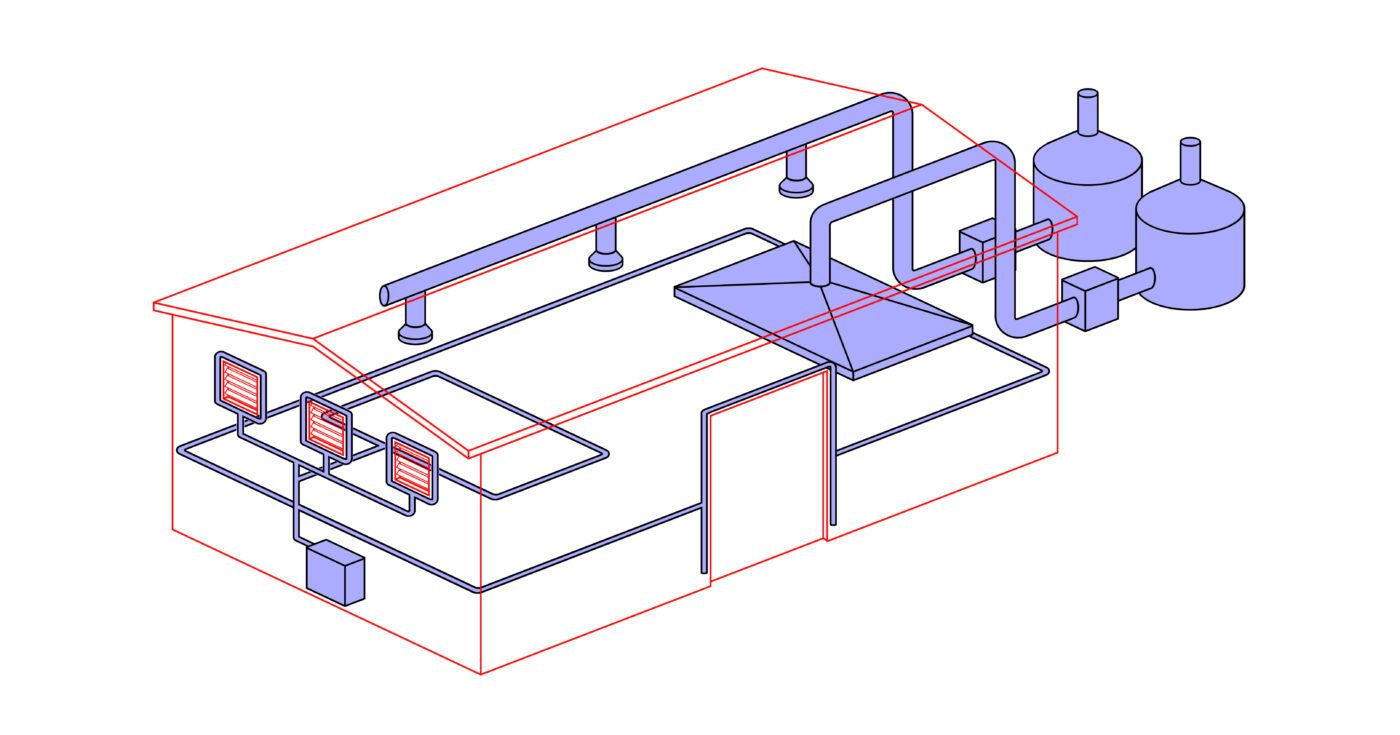

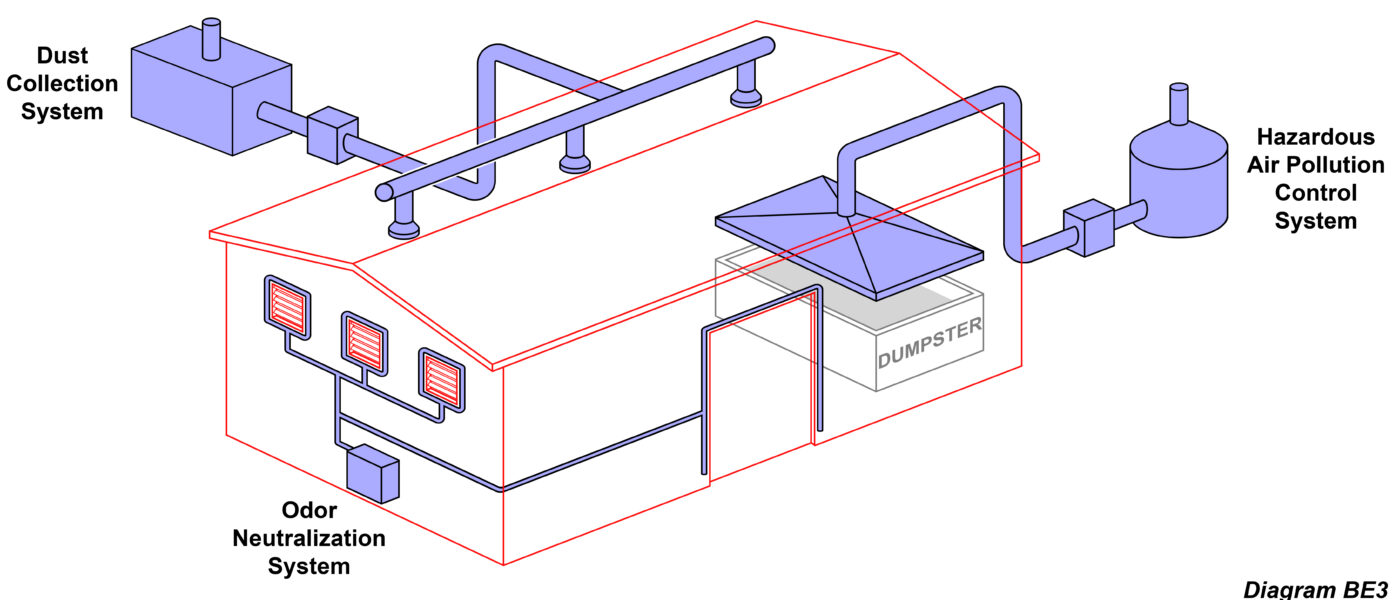

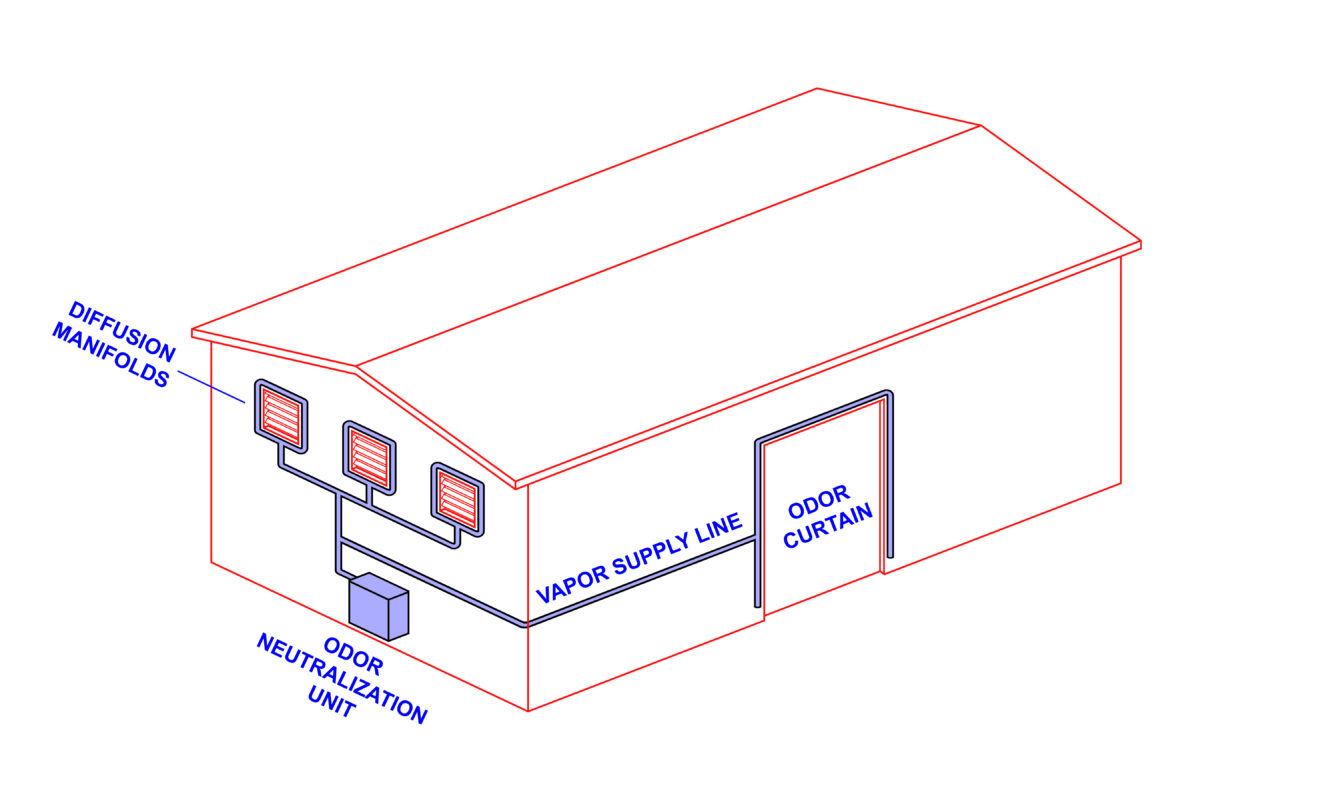

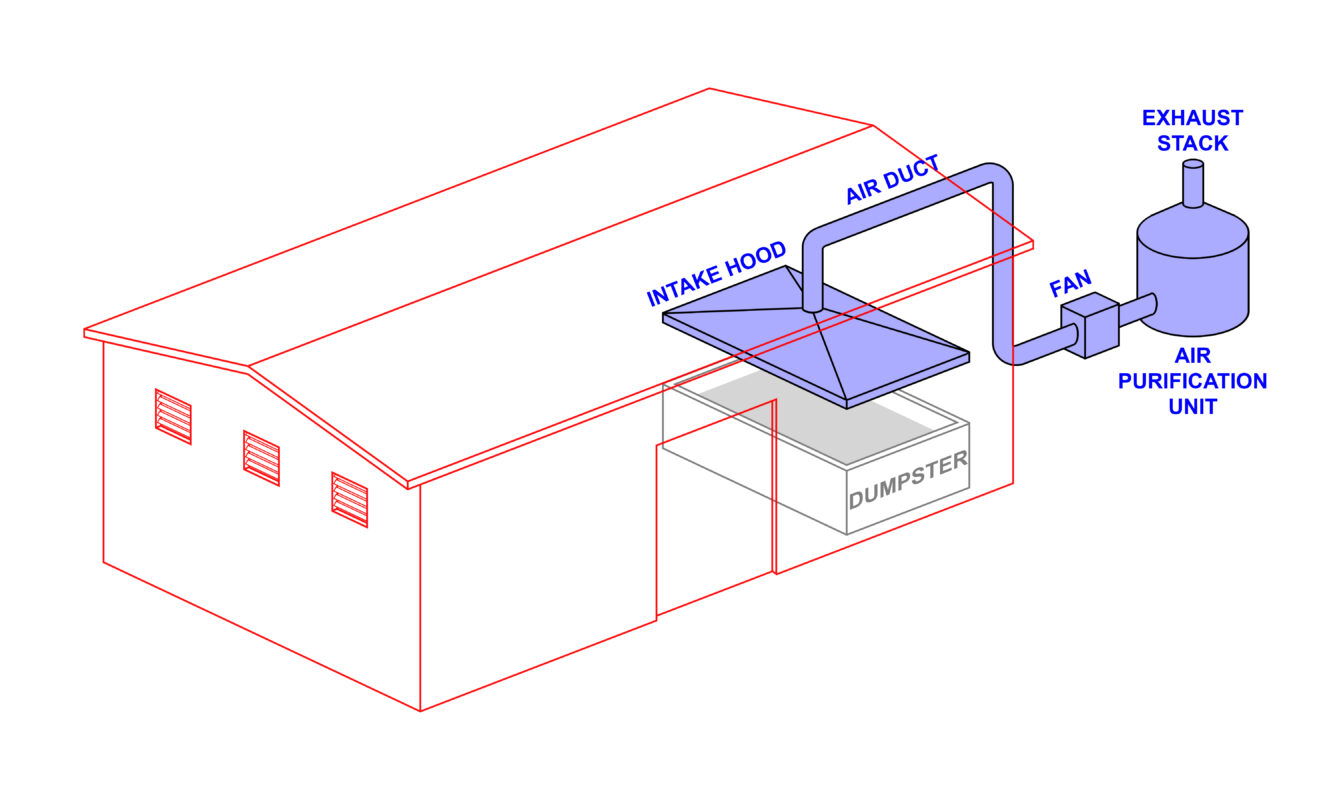

Diagram BE3 illustrates a building with a dust collection system treating interior air

along the back wall, an odor neutralization system treating vents on the left and a truck door on the front, as well as a hazardous air pollution control system treating a dumpster on the right.

It is important to note that there can be an overlap of treatment technologies, meaning a wet air scrubber can be used to treat dust and a high-efficiency wet scrubber to treat hazardous air pollution. Likewise, a carbon absorber can be used to treat malodors, as can a high-efficiency carbon absorber to treat hazardous compounds.

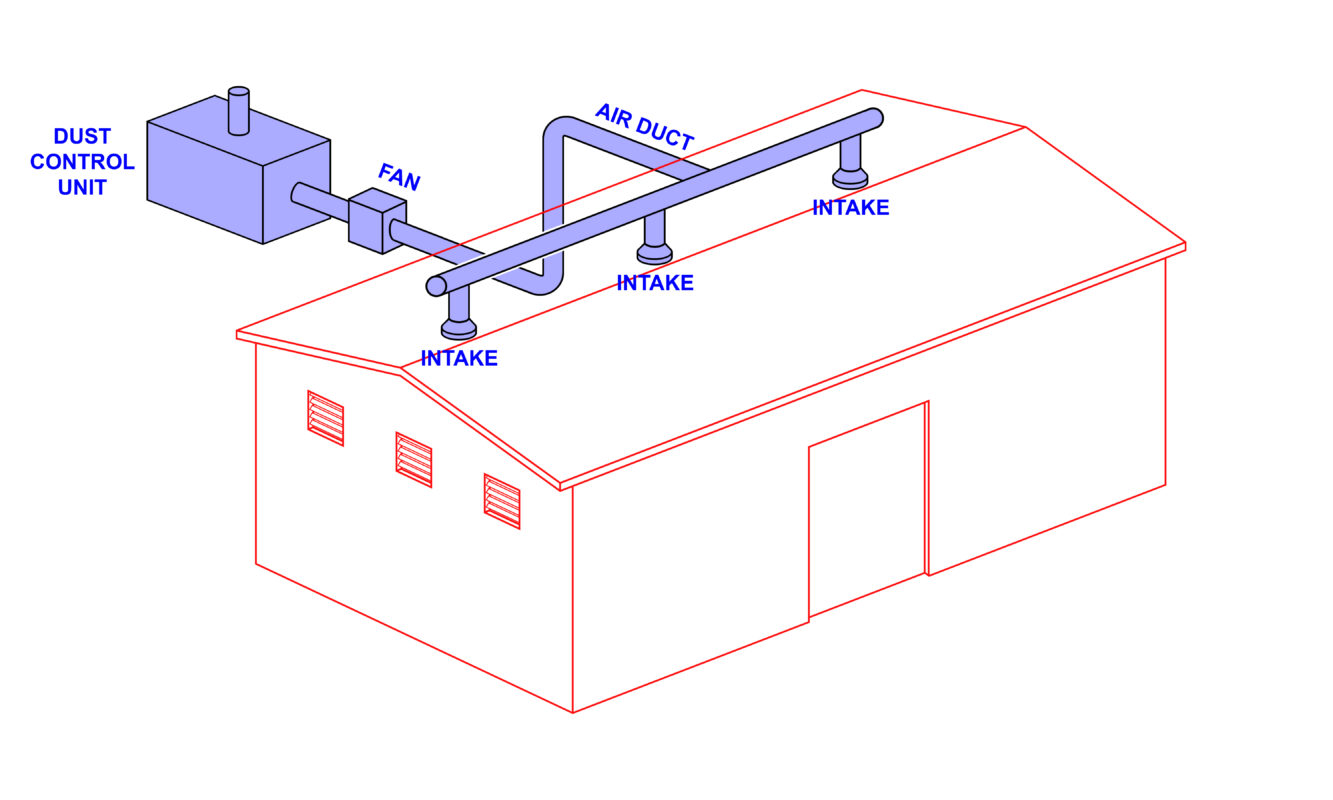

Dust Control

Dust emissions from buildings can be treated using dust suppression and dust

collection technologies. Dust suppression systems are engineered to prevent dust from becoming airborne by treating the source, whereas dust collection systems remove dust from the air after it has become airborne. Many facilities utilize both suppression and collection for maximum protection.

Dust suppression options include atomizing nozzle lines and fan units, both of which use water-based aerosol to wet the contaminant source in order to limit emissions. The most common dust collectors are bag houses, cartridge filters, and wet scrubbers.

Odor Control

It is best to treat odor at the source, i.e., the use of a scavenger or inhibitor to prevent hydrogen sulfide from being emitted from sewage or wastewater. However, source treatment is often not a feasible solution. Once malodors are emitted, they can be treated with air purification and/or odor neutralization technologies. Purification removes malodors from the air, whereas neutralization treats malodors in the open air.

Odor neutralization systems come in water-based aerosol and vapor phase varieties. Air purification options include air scrubbers, biofilters, and carbon absorbers.

Hazardous Air Pollution Control

Whenever possible, treat the pollution source before hazardous contaminants enter the air. For example, the acidification of manure can lower the pH, changing the ammonia equilibrium so that NH3 stays in solution rather than being emitted. When source treatment is not feasible, a hazardous air pollution control system must be used.

Standard options for hazardous air pollution control include high-efficiency versions of air scrubbers, biofilters, and carbon absorbers.

Conclusion

There are numerous technical facets, mathematical equations, and industry standards involved with air pollution control, with so much to learn that it would require several textbooks to cover the subject completely.

As previously mentioned, there can be overlaps with treatment technologies. For

instance, an advanced air purification system can have multiple stages, such as a bag filter module followed by a cartridge filter module and a carbon absorber module, thus filling the role of a dust control system, an odor control system, and a hazardous air pollution control system all in one.

This chapter is intended to provide a treatment plant operator or site manager with a foundation of fundamental principles to build upon. We look forward to the next

installment of Emission Report dedicated to dust control for buildings. Until then, be

safe.

– – –

Everything Environmental, All the Time. From your home, gym, office, and workplace habitats to the interior of your car, your neighborhood, your technological world, and the great outdoors.

Dedicated to clean air, and how to get there from here.